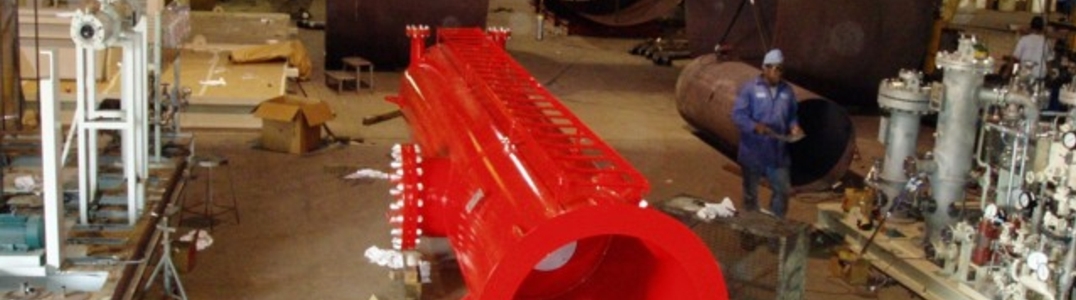

Fabrication capabilities: For over 25 years, we have been fabricating process equipment for

downstream industry (refining of the crude oil) as well for upstream industry - offshore and onshore.

Our ASME code certified fabrication shop with authorization to use "U" (manufacture of process vessels),

"R" (metalic reparis and/or alteration at the above location and extended for field reparis) and "NB" symbols.

We are also ABS certified for fabrication of Bulk Tanks, Surge tanks and Dust collector fabrication.

Located on 56 acres of stabilized lay down land, our fabrication shop is well equipment to handle all your needs.

Our ASME code certified fabrication shop utilize certified welders and experienced fitters for all fabrication

work. We have qualified Welding Procedure Specifications (WPS) for GMAW, GTAW, SAW, SMAW and FCAW

on file for most of the materials.

The shop produces the highest quality work while maintaining a safe working environment in the work place.

Equipment Design

The equipment is manufactured to meet or exceed industry standards given by : API, ASME Code Section

VIII Div.1, ANSI, API, IEEE, NEC, NEMA, NFPA, ISA, MSS, AWS, AISC and TEMA. Fabrication of equipment

to meet other standards and/or codes requirements like GOST, BS, DIN etc. is possible.

Our Engineering department evaluates customer specifications to design equipment for specific application.

We use extensive selection of PC- based applications and design software. Our engineer's perform all the design

and engineering necessary for the efficient construction and operation of your plant.

Our complete design and engineering capabilities encompass the following disciplines.

-

Civil Engineering

-

Mechanical Engineering

-

Environmental Engineering

-

Electrical Engineering

-

Process Engineering

-

Piping Design

Our own logistical department will provide the clients with in house services from lifting and rigging to

transportation.

Our sand blasting and paint facilities with 22,000 Sq/Ft indor, climate controlled building will provide you with

first class sand blasting with various range of blas media like: Black Beauty, Coal Slag, Steel Grit, Aluminum

Oxide, Walnutt Shell etc.

Some of our latest fabrication and projects accomplished:

- Dismantling of 55,000 BPD refinery, shipped to our shop and refurbished to ASME codes and API standard

- Dismantling of 20,000 BPD FCC unit, shipped to our shop for refurbishment

- Process design, process specifications and quality control of 10,000 BPD topping unit for Colombia

- Engineering and fabrication of 6,000 BPD topping refinery, control room, ancillary equipment to GOST

standards (Tokhorestk,

Russia)

- Engineering and fabrication of 2,500 BPD topping refinery for

remote location (Tunisia)

- Engineering and fabrication of Bouyancy Vessels for Mobil, Zafiro,

West Africa

- Fabrication of single lift offshore Fluid Storage and pump module

for Baroid Drilling Fluids (Division

of Halliburton Energy Services)

and end user Exxon

- Patented plant, design and fabrication for waste oil reclamation

(pilot projects on three occasion) for Shell,

Canada, Governmental

project - EPA, USA, Esso, Canada

- Process design and engineering package for 15,000 BPD topping

refinery, Bolivia S.A. - YPFB

- Process design and engineering package for 8,000 BPD topping

refinery, Chile S.A. - ENAP

- Design, Engineering and Fabrication of Crude oil metering skids

and Prover skids for

Ecopetrol, Colombia

- Engineering and fabrication of process package for crude

sweetening for Peten Petroleum,

Guatemala

- Thermal Cracking plant for processing heavy crude oil in the oil

field

- Process engineering, Detailed Engineering and Fabrication of 1,500

BPD sulphur unit for

Peten Petroleum, Guatemala

Representative List of clients: BP/AMOCO, ABB Lumus, Acreon Catalyst, Baker Hughes, Chevron, Curacao Petroleum Technologists, Dowell

Schlumberger, Excalibur Minerals, Fina Oil & Chemical, Foster Wheeler USA, Gulf of Suez Petroleum, Jordan

Petroleum Refining, Minioil JV, Mobil Oil, Peten Petroleum, Shell Offshore...